The VIDEOSCOPE XT is a truly industrial-grade borescope that has been designed for hazardous environments. This US-made inspection system has been tested and certified under MIL-STD 810G method 511.6 (explosive atmosphere) in accordance with UL standards for NFPA 70: class 1 division 2 requirements for hazardous locations. This borescope camera is also UL certified for Class I Division 2 hazardous locations. The system is Factory Mutual (FM) Compliant, CE Compliant, and built according to ISO 9001 standard.

.

This explosion-proof borescope camera is great for fuel tank inspections, police and military applications, customs and border protection, aviation and gas turbine, NDT, and power generation inspections.

.

This explosion-proof borescope camera is great for fuel tank inspections, police and military applications, customs and border protection, aviation and gas turbine, NDT, and power generation inspections.

EXPLOSION PROOF BORESCOPE CAMERA VIDEOSCOPE XT

Price

Prices are for the basic videoscope package and are subject to change. To find out the exact price of the set, write or call us.

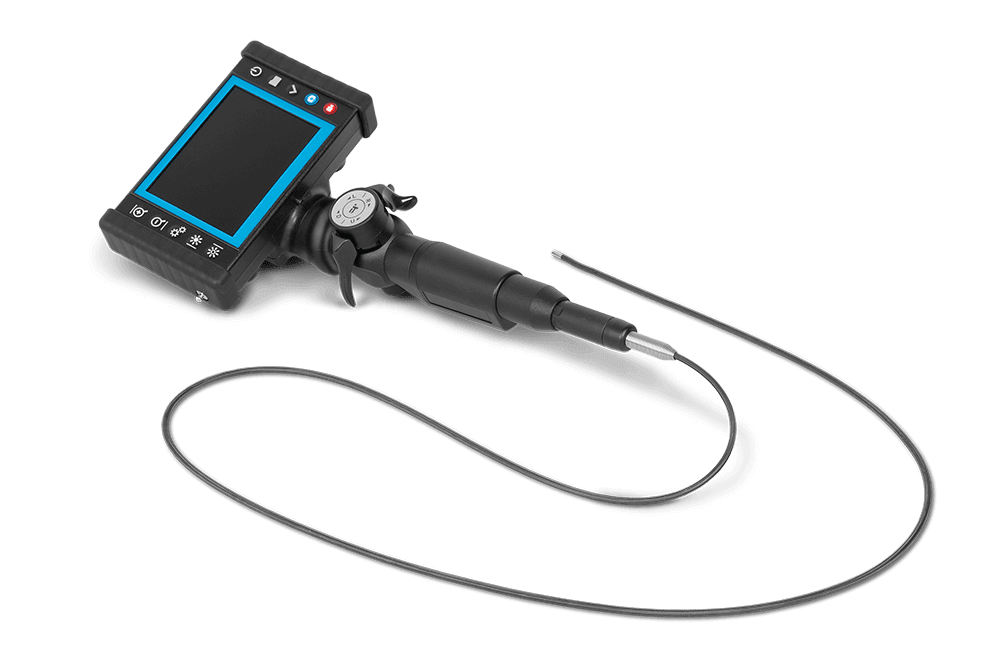

The Explosion Proof Borescope VIDEOSCOPE XT is a handheld, all-in-one portable unit that consists of an integrated Imaging HUB, operational Handle with articulation levers, and a flexible insertion probe with an articulating tip

The Imaging HUB

- Large Integrated Display (5.0"/12.7 cm) with VGA 640x480 Resolution

- Built-in 3.5x Digital Zoom

- 3-stage Adjustable LED Illumination

- Cold Fiber Optic Light in the Handle Means no Spark from LED in Explosive Environments

- Rechargeable Battery

- 32,000 Images or 500 hours of Video Can be Stored on 32GB SDHC Card

- Text Generator to Mark Captured Files

- Comparative Measurement

- Rubberized Protective Bumper

+ Full Specifications

Imaging HUB

— Display size: 5.0" (12.7 cm) TFT colour

— Display resolution: VGA (640 x 480 Pixel)

—Operating system: Real-time operating system, with on-screen menu

— User interface: Direct action keys / function keys / arrow keys

— Languages: English, German, Polish, French, Spanish, Italian, Turkish

— Video interface: Composite video-out (BNC)

— Power supply, primary: Rechargeable Li-ion battery (charger and battery are provided in a delivery set)

— Power supply, secondary: 12V adapter (optional accessories)

Documentation

— Video format: MPEG4 (.avi) (with time and date stamp)

— Image format: BMP (.bmp) (with time and date stamp)

— Storage: SDHC memory card up to 32 GB (FAT32) (8 GB is provided in delivery set)

Image Control

— Zoom: 16 steps digital zoom

— Invert: Horizontal and vertical image inversion

— Brightness: Adjustable

— Contrast: Adjustable

— Color: Adjustable

— Text annotation: Built-in text overlay generator

— Display size: 5.0" (12.7 cm) TFT colour

— Display resolution: VGA (640 x 480 Pixel)

—Operating system: Real-time operating system, with on-screen menu

— User interface: Direct action keys / function keys / arrow keys

— Languages: English, German, Polish, French, Spanish, Italian, Turkish

— Video interface: Composite video-out (BNC)

— Power supply, primary: Rechargeable Li-ion battery (charger and battery are provided in a delivery set)

— Power supply, secondary: 12V adapter (optional accessories)

Documentation

— Video format: MPEG4 (.avi) (with time and date stamp)

— Image format: BMP (.bmp) (with time and date stamp)

— Storage: SDHC memory card up to 32 GB (FAT32) (8 GB is provided in delivery set)

Image Control

— Zoom: 16 steps digital zoom

— Invert: Horizontal and vertical image inversion

— Brightness: Adjustable

— Contrast: Adjustable

— Color: Adjustable

— Text annotation: Built-in text overlay generator

Operational Handle

- ± 90° Rotatable Display Unit, alt. ±90° Rotatable Scope Handle

- Ergonomic Construction with One-touch Image Capture Button

- Two Mechanical Levers for Precise Articulation Control

Insertion Probe

• Working Length from 1.5 meters (4.9 ft) up to 10 meters (33 ft)

• Diameter: 4.0 mm (0.16") or 6mm (0.24") or 8mm (0.314")

• High-res. Advanced CMOS Camera, with 90-degree FOV

• 4 Way Tip Articulation with 360° Rotation

• Durable Tungsten-braided Probe

• Water-proof up to 14.7 psi

• Heat-resistant up to 176° F (+80°C) or 284° F (140°C) < 5 Minutes

• Diameter: 4.0 mm (0.16") or 6mm (0.24") or 8mm (0.314")

• High-res. Advanced CMOS Camera, with 90-degree FOV

• 4 Way Tip Articulation with 360° Rotation

• Durable Tungsten-braided Probe

• Water-proof up to 14.7 psi

• Heat-resistant up to 176° F (+80°C) or 284° F (140°C) < 5 Minutes

+ Full Specifications

Illumination

— Illumination Control: yes, 3-steps

— Type: High-power cold LED with high transmission fiberoptics

— Color Temperature: ca. 6500k

— Average Lamp Lifetime: ca. 5000 hours

Insertion Probe

— Diameter: 4.0mm, 6.0mm, 8mm

— Working Length: 4.9 - 33ft (1.5 - 10m)

— Articulation: 4-way, 360° control (Control Levers)

— Articulation Angle L/R | U/D: 4mm: 100°/100° | 100°/100° 6mm: 100°/100° | 160°/130°

— Integrated Objective Lens: 90° FOV

— Braid: Tungsten Braid on Poly-Urethane-Jacket

Construction

— Ergonomics: ± 90° rotatable Display Unit, alt. ±90° rotatable Scope Handle

— System Weight: 2.97lb (1.35kg) Operating Unit

— Dimensions: 180mm x 105mm x 45mm

— Housing: rugged PU, with integrated rubber shock caps

— Monitor Protection Class: IP53

Operating Environment

— Tip Operating Temperature: -13°F to 176°F (-25°C +80°C)

— System Operating Temperature: -13°F to 115°F (-25°C +46°C)

— Storage Temperature: -13°F to 140°F (-25°C +60°C)

— Relative Humidity: 95% max. – non-condensing

— Waterproof: Probe and distal end up to 14,7 psi (1 bar- 10,2 m H2O)

— Resistance: Probe to oils and 5% saline

Certificates

— UL Class I, Division 2: File # E477160

— Certified: ITVS17ATEX9828X

— MIL-STD-810G; Method 511.6

— NFPA 70: Class I, Division 2 Compliant

— Factory Mutual (FM) Compliant

— ISO 9001

— CE Compliant

— Military Aircraft Approved Videoscope

— Illumination Control: yes, 3-steps

— Type: High-power cold LED with high transmission fiberoptics

— Color Temperature: ca. 6500k

— Average Lamp Lifetime: ca. 5000 hours

Insertion Probe

— Diameter: 4.0mm, 6.0mm, 8mm

— Working Length: 4.9 - 33ft (1.5 - 10m)

— Articulation: 4-way, 360° control (Control Levers)

— Articulation Angle L/R | U/D: 4mm: 100°/100° | 100°/100° 6mm: 100°/100° | 160°/130°

— Integrated Objective Lens: 90° FOV

— Braid: Tungsten Braid on Poly-Urethane-Jacket

Construction

— Ergonomics: ± 90° rotatable Display Unit, alt. ±90° rotatable Scope Handle

— System Weight: 2.97lb (1.35kg) Operating Unit

— Dimensions: 180mm x 105mm x 45mm

— Housing: rugged PU, with integrated rubber shock caps

— Monitor Protection Class: IP53

Operating Environment

— Tip Operating Temperature: -13°F to 176°F (-25°C +80°C)

— System Operating Temperature: -13°F to 115°F (-25°C +46°C)

— Storage Temperature: -13°F to 140°F (-25°C +60°C)

— Relative Humidity: 95% max. – non-condensing

— Waterproof: Probe and distal end up to 14,7 psi (1 bar- 10,2 m H2O)

— Resistance: Probe to oils and 5% saline

Certificates

— UL Class I, Division 2: File # E477160

— Certified: ITVS17ATEX9828X

— MIL-STD-810G; Method 511.6

— NFPA 70: Class I, Division 2 Compliant

— Factory Mutual (FM) Compliant

— ISO 9001

— CE Compliant

— Military Aircraft Approved Videoscope

In the Box

Videoscope Unit

Battery

Battery Charger

Power Adapter

SD Memory Card

User's manual

Need advice? Ask our technical consultants who know the subject. They will answer your questions and help to scout out the best inspection solution for your application.

Questions and Answers

- Is this an intrinsically safe borescope camera? What is the difference between an explosion-proof and intrinsically safe borescope?The terms "explosion-proof" and "intrinsically safe" are both classifications of equipment suitable for use in hazardous environments

The difference is that an Explosion-proof (Ex) borescope has to be well sealed to contain any explosion originating within its housing and prevent sparks from within its housing from igniting vapors, gases, dust, or fibers in the air surrounding it.

Whereas Intrinsically Safe (IS) means that the probe is made using materials that limit energy, electrical and thermal, to a level below that required to ignite a specific hazardous atmospheric mixture. In simple terms, these devices are designed in such a way that they can't produce a spark that could ignite an explosive mixture, even in fault conditions.

As of our knowledge, at the present moment, there's no intrinsically safe video borescope available on the market.

This specific camera is not intrinsically safe; it is UL, MIL-STD-810G, and ATEX rated for an explosive atmosphere. - Are the MIL-STD 810G method 511.6, UL Class 1 Division 2, and ATEX Zone 2 certifications equal?The MIL-STD 810G Method 511.6, UL Class 1 Division 2, and ATEX Zone 2 certifications each represent different standards intended to regulate equipment for use in hazardous environments. While they all relate to safety in hazardous environments, they are not strictly equivalent, as they are developed by different bodies and are meant to address different types of hazards and operational conditions. Here's a brief overview of each:

MIL-STD 810G Method 511.6: This U.S. Military Standard defines the test methods for evaluating how well a device can handle operating in an environment where explosive atmospheres could be present. The testing procedures and requirements are extremely rigorous.

UL Class 1 Division 2: This is a safety standard set by Underwriters Laboratories (UL) for equipment intended to be used in places where a hazardous atmosphere is not normally present but could occur under abnormal conditions.

ATEX Zone 2: This is a certification based on the European ATEX directive, and it refers to a place in which an explosive atmosphere consisting of a mixture with air of dangerous substances in the form of gas, vapor, or mist is not likely to occur in normal operation but, if it does occur, will persist for a short period only.

While these certifications all deal with safety in hazardous environments, their requirements and the environments they apply to are not identical. To determine which certification is necessary for a specific device or application, it's important to understand the specific requirements of the environment and the local regulations and often to consult with a safety expert. - If the explosion-proof borescope model is certified for use in explosive atmospheres, does it mean it is protected over its lifespan?When an explosion-proof video borescope is certified for use in explosive atmospheres, it means the device meets rigorous standards and has passed stringent testing to ensure that it can safely operate in such environments. However, this certification does not automatically guarantee protection over the device's entire lifespan.

The device's safety can be affected by wear and tear, environmental conditions, misuse, and lack of maintenance. Therefore, regular inspections, appropriate usage, and good maintenance practices are vital to ensuring that the video borescope remains safe and functional throughout its lifespan. - Do I need specific training or a license to use an explosion-proof borescope?Generally, no special license is required to operate an explosion-proof borescope. However, operators are expected to have appropriate training to use such devices, particularly in hazardous environments, safely.

Also, it's important to note that regulations can vary by country, state/province, or industry. Therefore, we recommend contacting your local occupational safety and health administration or equivalent authority for the most accurate and up-to-date information. - Can explosion-proof borescopes be submerged in liquids or used in wet environments?Our video borescopes have waterproof insertion probes that can safely function in wet or submerged environments. Nevertheless, it is crucial to verify each model's specific ratings and limitations. Please feel free to ask our sales representative for more details.

- Are explosion-proof borescopes difficult to use?These borescopes are designed to be user-friendly. They come with ergonomic handheld articulation control and an intuitive interface. However, you can always contact our technical sales support with any questions.

- Where these videoscopes are made? How good is image quality?Our explosion-proof video borescopes are proudly made in the USA using precise German optics. They offer high-quality imaging and powerful illumination systems to provide clear visuals in dark environments.

- Is this a Food Grade Approved product? I see ATEX, but not Food grade compliance.This camera is not specifically rated for Food Grade. However, I know it is being used in some food processing plants. This unit can be safely cleaned with industrial-grade cleaning solutions. Please contact us if you have further questions at +1-877-613-2210

Do you have any questions?

They trust this videoscope for their visual inspection work

Multimedia

Explosion Proof Borescope with 4mm Insertion Probe Inspection Video Sample

UL Class 1 Division 2 Certified Borescope Camera VIDEOSCOPE-XT Video Sample

The Borescope's High-Quality Images

The exp-proof video borescope produces clear, high-resolution images, ensuring reliable and accurate detection. This enhances the user's ability to make informed decisions and maintain important systems.

Reviews

The System Full Description

- Industrial Grade Explosion Proof Borescope Camera

- Tested Under MIL-STD 810G method 511.6 (explosive environment)

- UL Certified for Class I Division 2 Hazardous Locations

- Factory Mutual (FM) Compliant

- CE Compliant

- ISO 9001

- Working Length from 1.5 meters (4.9 ft) up to 10 meters (33 ft)

- Diameter: 4.0 mm (0.16") or 6mm (0.24") or 8mm (0.314")

- High-resolution CMOS Camera, with 90-degree FOV

- Large Integrated Display (5.0"/12.7 cm) with VGA 640x480 Resolution

- Built-in Digital Zoom

- 3-stage Adjustable LED Illumination

- Cold Fiber Optic Light in the Handle Means no Spark from LED in Explosive Environments

- 4 Way Tip Articulation with 360° Rotation

- Rechargeable 6h Battery

- 32,000 Images or 500 hours of Video Can be Stored on 32GB SDHC Card

- Portable, Robust, Durable Set in a Hard Plastic Carrying Case

- Made in the USA

The explosion-proof borescope camera VIDEOSCOPE-XT is great for fuel tank inspections, police and military applications, customs and border protection, aviation and gas turbine, NDT, and power generation inspections.

This VIDEOSCOPE-XT inspection system is a full set, with a built-in monitor and integrated design. These units feature a great color CMOS camera chip in the tip of the probe, which will provide you with a small bend radius to access tight areas or corners. The camera chip has a 90-degree field of view, 4-way tip articulation, with 360-degree rotation, controlled via 2 knobs on the ergonomic handle for easy one-handed operation. The extra powerful LED light is located in the handle, so there is no chance of a spark in explosive environments, and it has 3-step intensity control. The live image is displayed on a large 5" color TFT monitor, with image and video capture to an SD memory card. These units also feature digital zoom, text input for captured files, comparative measurement, and a rechargeable battery for portable use.

The VIDEOSCOPE-XT explosion proof borescope cameras are available in a 4mm (0.16") diameter probe with standard lengths of 1.5 meters (4.9 feet) to 4 meters (13.1 feet), or there are larger 6mm (0.2.4") and 8mm (0.314") diameter probes with lengths from 1.5 meters (4.9 feet) to 10 meters (33 feet), with full tip articulation.

Note: VIDEOSCOPE-XT is a specially ordered product. Conditions apply. Call for details.

*To learn more about explosive atmosphere specifications read this page

Explosive Atmosphere and Visual Inspection

General Specifications of Explosive Environment and MIL-STD-810 Method 511

What is a Hazardous Environment?

Any location where explosions or fire may exist due to the presence of flammable liquids, gases, vapors, dust, or fibers. This is a general listing, but in all honesty, no one can truly identify all of the locations that can be hazardous or generate guidelines that would work for every possible location or situation out there. For materials to combust, a combustible substance must be around oxygen and something that creates a spark or a source of ignition. This can include gasoline, paint thinner, decomposing materials, or naturally occurring gases. With regards to the videoscopes that we sell, all of these units are currently classified for use in Class I Division 2 hazardous environments, as defined in the National Fire Protection Association Code (NFPA 70), Article 500, and tested using MIL-STD-810G, Method 511.6, Procedure I. We do not currently know of any videoscopes that are classified for Class I Division 1 use or that are intrinsically safe. We are working on this certification process for the XT line, though. Before using these products, you must know or be able to confirm the classification level of the hazardous location you will be working in or inspecting to ensure that the proper criteria are met.

What does explosion proof mean?

To understand explosion proof, you need to look at the context of the term and the organization that defined it. The National Fire Protection Association (NFPA) began publishing the National Electric Code (NEC®) in 1897. The NEC® is also known as NFPA 70 and ANSI/NFPA 70 from its inclusion in the body of NFPA codes. The NEC® includes definitions for several types of protection techniques acceptable when designing products for use in hazardous (classified) locations: Explosion proof, dust ignition proof, dust-tight, purged/pressurized, intrinsically safe, and hermetically sealed. These definitions set the criteria that must be met by all components installed or used in hazardous (classified) locations. To meet the criteria for the explosion-proof rating, an enclosure must be able to contain any explosion originating within its housing and prevent sparks from within its housing from igniting vapors, gases, dust, or fibers in the air surrounding it. Therefore, explosion proof, when referring to electrical enclosures, does not mean that it is able to withstand an exterior explosion. Instead, it is the enclosure's ability to prevent an internal spark or explosion from causing a much larger blast. Additionally, the NEC states that equipment must meet the temperature requirements of the specific application in which it is to be installed or used. This means that the operating temperature of the device cannot be greater than the lowest ignition/combustion temperature of the gases or dusts in the atmosphere where it is being used.

(Source)

How does the classification system work?

Within North America, hazardous locations are defined using a combination of classes and divisions as follows:

Classes

Class I – A location made hazardous by the presence of flammable gases or vapors that may be present in the air in quantities sufficient to produce an explosive or ignitable mixture

Class II – A location made hazardous by the presence of combustible or electrically conductive dust

Class III - A location made hazardous by the presence of easily ignitable fibers or flyings in the air but not likely to be in suspension in quantities sufficient to produce ignitable mixtures

Divisions

Division 1 – A location where a classified hazard exists or is likely to exist under normal conditions

Division 2 – A location where a classified hazard does not normally exist but is possible to appear under abnormal conditions

The U.S. and Canada have recently revised codes to recognize an international 3-Zone classification system for equipment used in hazardous locations. These are and will continue to come into effect moving forward.

Zone 0 – An area in which an explosive gas atmosphere is continuously present for a long period of time

Zone 1 – An area in which an explosive atmosphere is likely to occur in normal operation

Zone 2 – An area in which an explosive gas atmosphere does not normally exist.

The zone classification system can be defined by hours as well, with Zone 0 having an ignitable concentration of flammable gases, vapors, or liquids present continuously or for long periods of time under normal operating conditions defined as over 1000 hours/year, Zone 1 defined as 10-1000 hours/year, and Zone 2 defined as ignitable concentrations of flammable gases, vapors, or liquids only present for under 10 hours/year.

(Source)

Sources

National Fire Protection Association

ATEX Directives

Underwriters Laboratories (UL)

How are these protection techniques rated?

Each of the protection techniques mentioned above is permitted for use only in very specific applications. For example, components and equipment complying with dust-tight specifications are approved for use in Class II, Division 2, or Class III, Division 1, or 2 locations, while those listed as explosion-proof are approved for use in Class I, Division 1, or 2 locations.

Often, those products listed at a higher classification level surpass the requirements for lower classifications. The NEC® explicitly states, "Equipment that has been identified for a Division 1 location shall be permitted in a Division 2 location of the same class, group, and temperature class," thereby complying with requirements for the Division 2 areas [ANSI/NFPA 70:500.8(A)(2)].

(Source)

What is MIL-STD-801G Method 511?

This standard is a United States Military Standard to test equipment's limits in various environmental conditions where it is expected to be used or transported. It describes in detail testing procedures designed to determine how equipment holds up under a variety of conditions the equipment may encounter while being used, transported and stored. These conditions include temperature, impact (shock), vibration, humidity, explosive atmosphere, and more. This method is performed to demonstrate the ability of the material to operate in explosive atmospheres without causing ignition or to demonstrate that an explosive or burning reaction occurring within encased material will be contained and will not propagate outside the test unit.

Method 511 deals with 2 procedures, Procedure I where the unit operates in an explosive atmosphere without igniting the air/fuel mixture environment, and Procedure II which determines the ability of the test unit to contain an explosion or flame that is the result of an internal malfunction. Procedure II specifically relates to atmospheres in a space in which flammable fluids or vapors exist, or can exist, either continuously or intermittently. These tests involve placing the item inside a chamber filled with an explosive mixture and keeping this at the maximum temperature the item may experience. For Procedure 1, operate the unit in this explosive atmosphere to determine if it will ignite the mixture.

It is worth noting that during testing in vapors, the altitude changes, as does the ambient temperature - this is what makes it significantly more dynamic than the straightforward UL tests - the change in altitude and temperature create positive pressure and a vacuum environment in an attempt to "draw" vapors into the unit.

What is a Hazardous Environment?

Any location where explosions or fire may exist due to the presence of flammable liquids, gases, vapors, dust, or fibers. This is a general listing, but in all honesty, no one can truly identify all of the locations that can be hazardous or generate guidelines that would work for every possible location or situation out there. For materials to combust, a combustible substance must be around oxygen and something that creates a spark or a source of ignition. This can include gasoline, paint thinner, decomposing materials, or naturally occurring gases. With regards to the videoscopes that we sell, all of these units are currently classified for use in Class I Division 2 hazardous environments, as defined in the National Fire Protection Association Code (NFPA 70), Article 500, and tested using MIL-STD-810G, Method 511.6, Procedure I. We do not currently know of any videoscopes that are classified for Class I Division 1 use or that are intrinsically safe. We are working on this certification process for the XT line, though. Before using these products, you must know or be able to confirm the classification level of the hazardous location you will be working in or inspecting to ensure that the proper criteria are met.

What does explosion proof mean?

To understand explosion proof, you need to look at the context of the term and the organization that defined it. The National Fire Protection Association (NFPA) began publishing the National Electric Code (NEC®) in 1897. The NEC® is also known as NFPA 70 and ANSI/NFPA 70 from its inclusion in the body of NFPA codes. The NEC® includes definitions for several types of protection techniques acceptable when designing products for use in hazardous (classified) locations: Explosion proof, dust ignition proof, dust-tight, purged/pressurized, intrinsically safe, and hermetically sealed. These definitions set the criteria that must be met by all components installed or used in hazardous (classified) locations. To meet the criteria for the explosion-proof rating, an enclosure must be able to contain any explosion originating within its housing and prevent sparks from within its housing from igniting vapors, gases, dust, or fibers in the air surrounding it. Therefore, explosion proof, when referring to electrical enclosures, does not mean that it is able to withstand an exterior explosion. Instead, it is the enclosure's ability to prevent an internal spark or explosion from causing a much larger blast. Additionally, the NEC states that equipment must meet the temperature requirements of the specific application in which it is to be installed or used. This means that the operating temperature of the device cannot be greater than the lowest ignition/combustion temperature of the gases or dusts in the atmosphere where it is being used.

(Source)

How does the classification system work?

Within North America, hazardous locations are defined using a combination of classes and divisions as follows:

Classes

Class I – A location made hazardous by the presence of flammable gases or vapors that may be present in the air in quantities sufficient to produce an explosive or ignitable mixture

Class II – A location made hazardous by the presence of combustible or electrically conductive dust

Class III - A location made hazardous by the presence of easily ignitable fibers or flyings in the air but not likely to be in suspension in quantities sufficient to produce ignitable mixtures

Divisions

Division 1 – A location where a classified hazard exists or is likely to exist under normal conditions

Division 2 – A location where a classified hazard does not normally exist but is possible to appear under abnormal conditions

The U.S. and Canada have recently revised codes to recognize an international 3-Zone classification system for equipment used in hazardous locations. These are and will continue to come into effect moving forward.

Zone 0 – An area in which an explosive gas atmosphere is continuously present for a long period of time

Zone 1 – An area in which an explosive atmosphere is likely to occur in normal operation

Zone 2 – An area in which an explosive gas atmosphere does not normally exist.

The zone classification system can be defined by hours as well, with Zone 0 having an ignitable concentration of flammable gases, vapors, or liquids present continuously or for long periods of time under normal operating conditions defined as over 1000 hours/year, Zone 1 defined as 10-1000 hours/year, and Zone 2 defined as ignitable concentrations of flammable gases, vapors, or liquids only present for under 10 hours/year.

(Source)

Sources

National Fire Protection Association

ATEX Directives

Underwriters Laboratories (UL)

How are these protection techniques rated?

Each of the protection techniques mentioned above is permitted for use only in very specific applications. For example, components and equipment complying with dust-tight specifications are approved for use in Class II, Division 2, or Class III, Division 1, or 2 locations, while those listed as explosion-proof are approved for use in Class I, Division 1, or 2 locations.

Often, those products listed at a higher classification level surpass the requirements for lower classifications. The NEC® explicitly states, "Equipment that has been identified for a Division 1 location shall be permitted in a Division 2 location of the same class, group, and temperature class," thereby complying with requirements for the Division 2 areas [ANSI/NFPA 70:500.8(A)(2)].

(Source)

What is MIL-STD-801G Method 511?

This standard is a United States Military Standard to test equipment's limits in various environmental conditions where it is expected to be used or transported. It describes in detail testing procedures designed to determine how equipment holds up under a variety of conditions the equipment may encounter while being used, transported and stored. These conditions include temperature, impact (shock), vibration, humidity, explosive atmosphere, and more. This method is performed to demonstrate the ability of the material to operate in explosive atmospheres without causing ignition or to demonstrate that an explosive or burning reaction occurring within encased material will be contained and will not propagate outside the test unit.

Method 511 deals with 2 procedures, Procedure I where the unit operates in an explosive atmosphere without igniting the air/fuel mixture environment, and Procedure II which determines the ability of the test unit to contain an explosion or flame that is the result of an internal malfunction. Procedure II specifically relates to atmospheres in a space in which flammable fluids or vapors exist, or can exist, either continuously or intermittently. These tests involve placing the item inside a chamber filled with an explosive mixture and keeping this at the maximum temperature the item may experience. For Procedure 1, operate the unit in this explosive atmosphere to determine if it will ignite the mixture.

It is worth noting that during testing in vapors, the altitude changes, as does the ambient temperature - this is what makes it significantly more dynamic than the straightforward UL tests - the change in altitude and temperature create positive pressure and a vacuum environment in an attempt to "draw" vapors into the unit.

What is an explosion-proof borescope, and what are its applications in various industries?

An explosion-proof borescope is a specialized visual inspection device designed to operate safely in potentially hazardous environments where there is a risk of explosion due to the presence of flammable gases, vapors, or dust. These borescopes are constructed using materials and components that prevent the ignition of the surrounding atmosphere. To ensure their safe use in such environments, they are officially certified to meet specific safety standards and regulations, such as UL, ATEX, MIL-STD 810G.

Oil and gas

Explosion-proof video borescopes are used for inspecting pipelines, storage tanks, valves, and other components in refineries, offshore drilling platforms, and production facilities where explosive gases may be present.Petrochemical

These devices can be used to inspect equipment and infrastructure in chemical plants and processing facilities, where volatile chemicals and gases can create potentially explosive atmospheres.Power generation

Explosion-proof borescopes can be employed to inspect components in power plants, particularly those using natural gas or other combustible fuels, for signs of wear, damage, or contamination that could lead to equipment failure or an explosion.Law enforcement and border control

Explosion-proof borescope cameras allow law enforcement and border control officers to safely inspect suspicious packages or enclosed spaces for explosives, illicit substances, or hidden contraband without triggering a potential detonation.Food and beverage

Food and beverage: These borescopes are useful for inspecting equipment and storage facilities where explosive dusts, such as grain or sugar, may accumulate.

AerospaceExplosion-proof borescopes can be used to inspect fuel systems, engines, and other components in aircraft, where combustible materials and fuels may create a hazardous environment.Mining and minerals

In mining operations, explosion-proof borescopes can be used to inspect equipment and infrastructure in areas where explosive gases or dust may be present, such as in coal mines or processing plants.Waste management

They can be employed to inspect equipment and facilities in waste treatment plants, landfills, and other waste management operations where flammable gases, such as methane, may accumulate.